Plastic Pipe Machinery Manufacturer

- YUYU Plastic Machinery delivers high-performance PVC/PE/PP pipe equipment designed for efficient, modern, and reliable pipe production solutions.

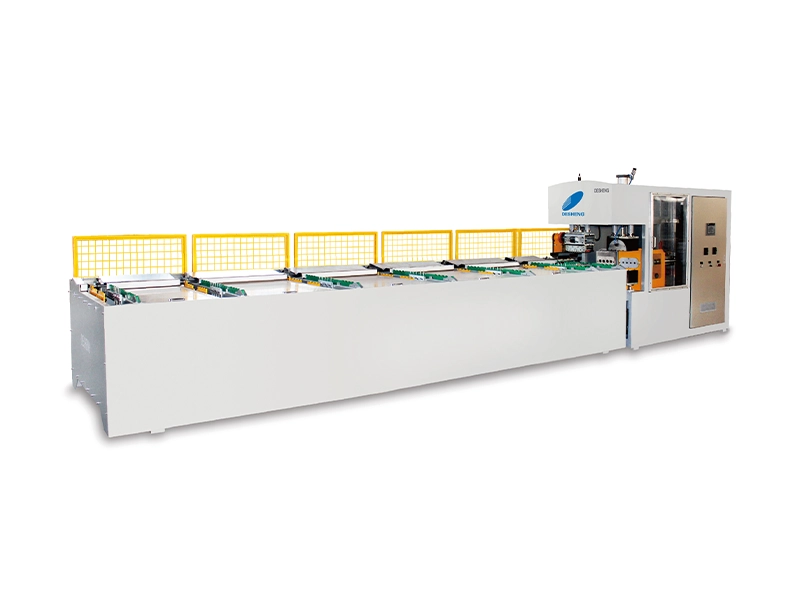

- Belling Machine

- Pipe Bending Machines

- Pipe Slotting Machine

- Pipe Threading Machine

- Pipe Perforating Machine

About Us

Who We Are

- Jiangsu Yuyu Plastic Machinery Co., Ltd. and Changzhou Desheng Plastic Machinery Co., Ltd. have been dedicated to the production of auxiliary equipment for plastic pipe manufacturing since 2003. We specialize in machines for PVC pipes, PVC corrugated pipes, PP pipes, and PE pipes, including belling/socketing machines, slotting machines, thread cutting machines, bending machines, and other plastic pipe processing equipment.

Product

WHAT WE OFFER

- Our main products include various PVC, PVC corrugated, PP, and PE pipes of belling machines, slotting machines, thread cutting machines, and bending machines for pipe post-processing.

Belling Machine

- Pipe diameters ranging from 16mm to 1600mm.

- Up to 12 pipes can be expanded per cycle.

- R-type/ Rectangular type/smooth(U) type/Rieber type.

- Provide automatic and semi-automatic machine.

Pipe Bending Machine

- Supports 30°, 45°, 60°, 90° bending angles.

- Pipe diameters ranging from 20mm to 160mm.

- Supports pipe lengths from 220mm to 1520mm.

- water-cooled for shape retention.

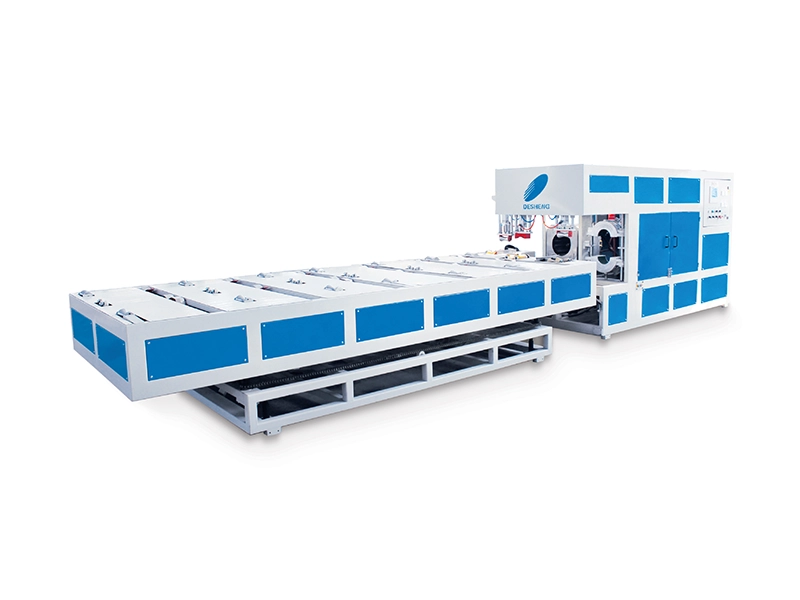

Pipe Threading Machine

- Pipe diameters ranging from 1/2" to 630mm.

- Support V-type/T-type outer thread and T-type inner thread.

- Support pipe length ranging from 3m to 6m.

- Automatic operation.

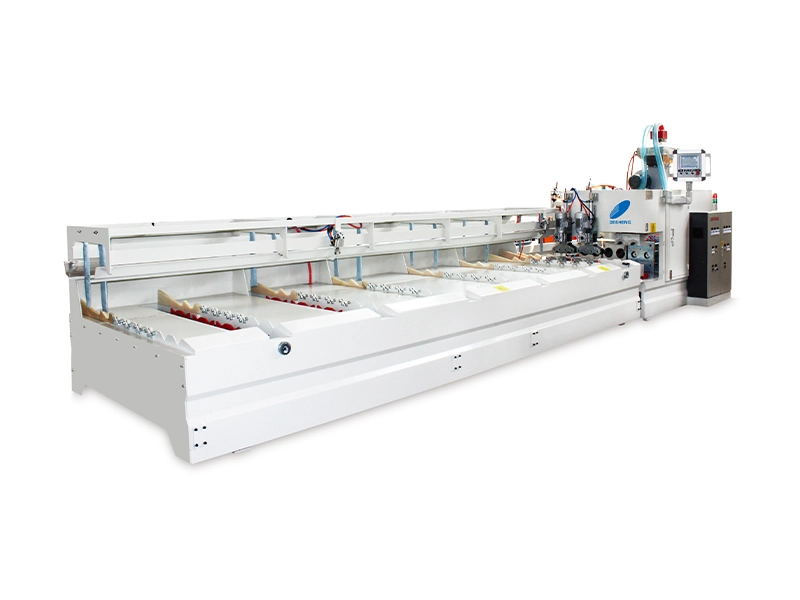

Pipe Slotting Machine

- Pipe diameters ranging from 1.5" to 630mm.

- Support pipe length ranging from 3m to 6m.

- Support vertical and horizontal thread type.

- Precisely cuts multiple narrow slots.

Hot Sale

Main Products

Professional Field

First-class technology with over 15 years’ experience. We professionally customize machinery solutions tailored to your specific needs.

After-sales Support

Backed by recognized technical experts and a skilled sales team, our annual output exceeds 200 sets, ensuring industry-wide trust.

Team Support

With pre-sales consultation and reception, we offer advanced production control and a comprehensive after-sales service system.

Daily Updated

Our Latest Articles

January 23, 2026

In the world of pipe manufacturing, efficiency is key to maintaining competitive pricing, meeting production targets, and ensuring high-quality output. One essential tool in achieving these objectives is the belling machine. Belling machines are used in the production of pipes, specifically to form the bell-shaped end of pipes that allows for secure and leak-proof connections during installation.

December 19, 2025

Sockets (also called bells) look simple, but they’re a tightly controlled “interface part”: the pipe must seal, align, and survive handling without cracks or leaks. Because socket formation involves heating, reshaping, vacuum/pressure forming, calibration, and cooling, small process drifts can create repeatable defects.