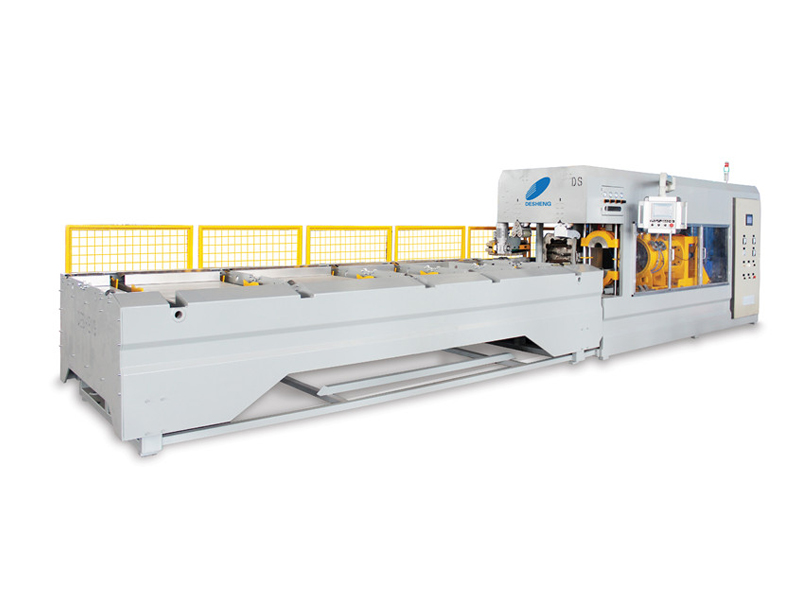

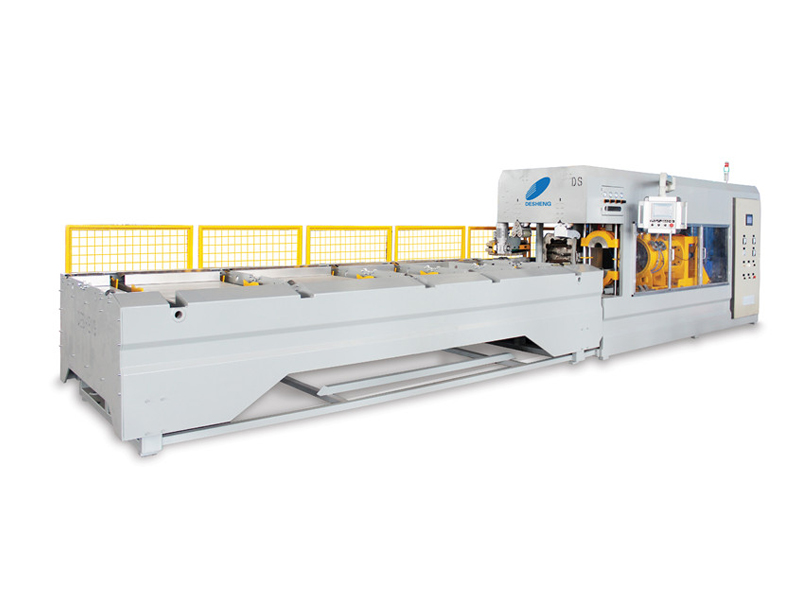

DS315-NI Belling machine – Yuyu Detail:

| Pipe

standards

|

Model | DS315-NI |

| standard | U-PVC pipes | |

| Diameter | 110mm – 315mm | |

| Pipe Length | 6m | |

| Heating

|

Heating way | 1 oven (Option: 2 ovens)

Stainless steel body, long service life |

| Pipe Rotary | Clockwise and anti-clockwise | |

| Electrical

|

PLC and Screen | Siemens |

| low-voltage apparatus | Schneider, Omron | |

| Total Power | 25KW | |

| Pneumatic | Compressed air pressure | 0.6Mpa |

| Water | Water pressure | 0.4Mpa |

| Hydraulic | Hydraulic pressure | 6.3Mpa |

| Equipment

appearance

|

Machine type | Automatic, single line, one pipes per cycle |

| Machine dimension | 8000mm(L)×2000mm(W)×2100mm(H) | |

| Machine weight | 4500kg | |

| Operating principle

|

U-type | Pushing the mould into pipe directly |

| R-type | With ext - pressure and collapsible mandrel | |

| Cooling type | Water – cooling | |

| Machine speed | Max. 60S/pipe |

| No. | Items | YUYU* Desheng |

| 1. | Company scale | Covers an area of 53,000 sq.m. with more than 20 years’ experience for machinery. With over 100 staff group. |

| 2. | Certification | CE; ISO; high-tech enterprise; with patents |

| 3. | Electrical components | Siemens, Mitsubishi, Schneider, Omron, Autonics, etc Taiwan Ashun, Yinchuan Changcheng, Or Taiwan Ashun |

| 4. | Feature | Customized project is welcome |

| 5 | R-type working way | 2 ways: suitable for thin and thick wall thickness pipes.No.1 segment in first, after heating, pipe insert on the moulds, segment out, increase ext- pressure to take sharp.No.2 segment out first, after heating, pipe insert on the moulds, increase ext-pressure to take sharp. |

| 6 | Movable Control box | 1.Control device is moveable and can be near to Belling station, and easy for adjustment.2.New control system with rocker arm, come with Alarm warning system. (When machine is working, if any problems happen, Alarm light will be Activate and operator can check the problem on touch screen panel, then re-start machine quickly.3. New type of Touch Screen can store up to 30 different parameter and settings for different pipe size |

| 7 | Problem alarm | If machine stop, and you can check the problem on touch screen, and restart the machine soon. |

Product detail pictures:

Related Product Guide:

Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs for DS315-NI Belling machine – Yuyu, The product will supply to all over the world, such as: Azerbaijan , Doha , Jersey , We only supply quality items and we believe this is the only way to keep business continue. We can supply custom service too such as Logo, custom size, or custom merchandise etc that can according to customer's requirement.

A good manufacturers, we have cooperated twice, good quality and good service attitude.

-

Quality Inspection for Double Head Chamfering M...

-

Low price for Pvc Belling Machine - RBM500-NI ...

-

Manufactur standard L Type Pipe Belling Machine...

-

Manufacturer for Slotting Machine - DS114-SA A...

-

Factory made hot-sale Single Head Tube Chamferi...

-

PriceList for Mechanical Slotting Machines - D...