OEM Manufacturer Automatic Pipe Belling Machine - DS160 Belling machine – Yuyu Detail:

| Pipe

standards

|

Model | DS160 |

| standard | U-PVC pipes | |

| Diameter | 40mm – 160mm | |

| Pipe Length | 6m | |

| Heating

|

Heating way | 1 oven (Option: 2 ovens)

Stainless steel body, long service life |

| Pipe Rotary | Clockwise and anti-clockwise | |

| Electrical

|

PLC and Screen | Siemens |

| low-voltage apparatus | Schneider, Omron | |

| Total Power | 12KW | |

| Pneumatic | Compressed air pressure | 0.6Mpa |

| Water | Water pressure | 0.4Mpa |

| Hydraulic | Hydraulic pressure | 5.0Mpa |

| Equipment

appearance

|

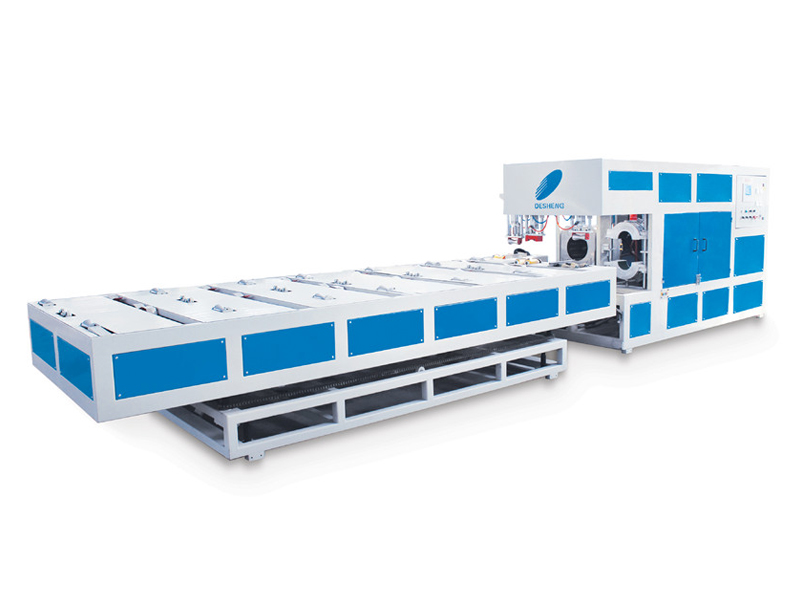

Machine type | Automatic, single line, one pipes per cycle |

| Machine dimension | 7350mm(L)×1450mm(W)×1850mm(H) | |

| Machine weight | 2200kg | |

| Operating principle

|

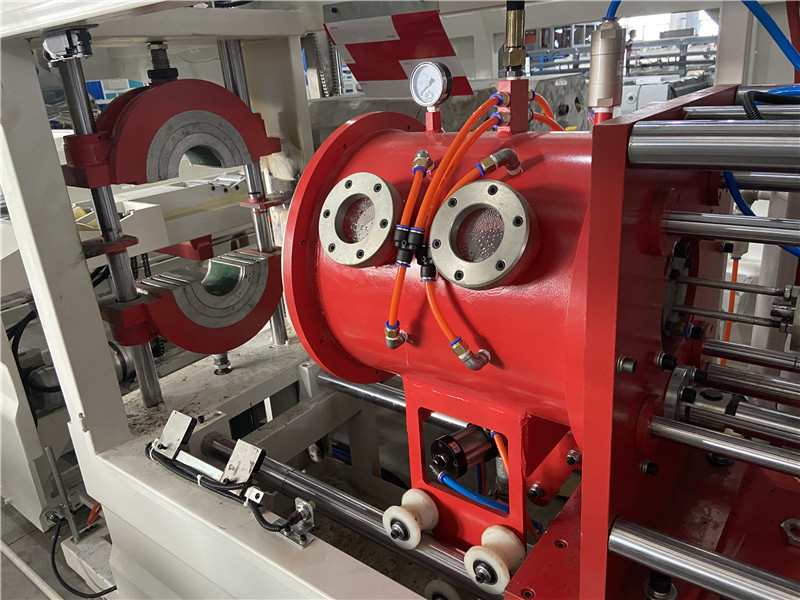

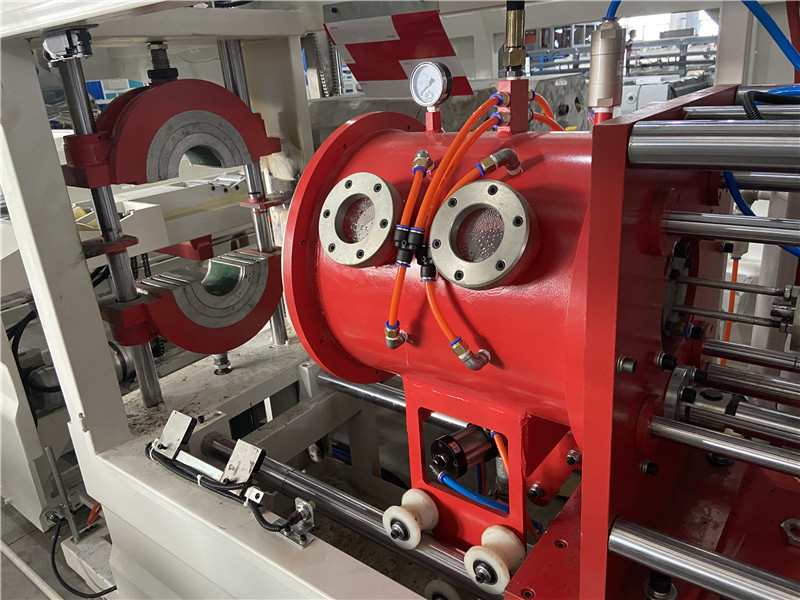

U-type | Pushing the mould into pipe directly |

| R-type | With ext - pressure and collapsible mandrel | |

| Cooling type | Water – cooling | |

| Machine speed | Max. 50S/pipe |

| No. | Items | YUYU* Desheng |

| 1. | Company scale | Covers an area of 53,000 sq.m. with more than 20 years’ experience for machinery. With over 100 staff group. |

| 2. | Certification | CE; ISO; high-tech enterprise; with patents |

| 3. | Electrical components | Siemens, Mitsubishi, Schneider, Omron, Autonics, etc Taiwan Ashun, Yinchuan Changcheng, Or Taiwan Ashun |

| 4. | R-type working way | 2 ways: suitable for thin and thick wall thickness pipes.No.1 segment in first, after heating, pipe insert on the moulds, segment out, increase ext- pressure to take sharp.No.2 segment out first, after heating, pipe insert on the moulds, increase ext-pressure to take sharp. |

| 5. | options |

|

Product detail pictures:

Related Product Guide:

Excellent 1st,and Client Supreme is our guideline to deliver the ideal provider to our prospects.Nowadays, we have been seeking our best to become certainly one of the most effective exporters in our discipline to meet shoppers more require for OEM Manufacturer Automatic Pipe Belling Machine - DS160 Belling machine – Yuyu, The product will supply to all over the world, such as: Johor , Bulgaria , Estonia , In the future, we promise to keep offer the high quality and more cost-effective products, the more efficient after sales service to our all customers all over the world for the common development and the higher benefit.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.

-

2019 Latest Design Double Oven Belling Machine ...

-

Factory For Chamfering Machine Made In China - ...

-

2019 Good Quality Plastic Machine - DS250P Cor...

-

Special Design for O Ring Belling Machine - DS...

-

Competitive Price for Belling Machine European ...

-

PriceList for Pipe Belling Expanding Machine - ...