OEM Manufacturer Automatic Pipe Belling Machine - DS500 Belling machine – Yuyu Detail:

| Pipe

standards

|

Model | DS500 |

| standard | U-PVC pipes | |

| Diameter | 250mm – 500mm | |

| Pipe Length | 6m | |

| Heating

|

Heating way | 1 oven (Option: 2 ovens)

Stainless steel body, long service life |

| Pipe Rotary | Clockwise and anti-clockwise | |

| Electrical

|

PLC and Screen | Siemens |

| low-voltage apparatus | Schneider, Omron | |

| Total Power | 35KW | |

| Pneumatic | Compressed air pressure | 0.6Mpa |

| Water | Water pressure | 0.4Mpa |

| Hydraulic | Hydraulic pressure | 6.3Mpa |

| Equipment

appearance

|

Machine type | Automatic, single line, one pipes per cycle |

| Machine dimension | 8800mm(L)×2850mm(W)×2250mm(H) | |

| Machine weight | 7500kg | |

| Operating principle

|

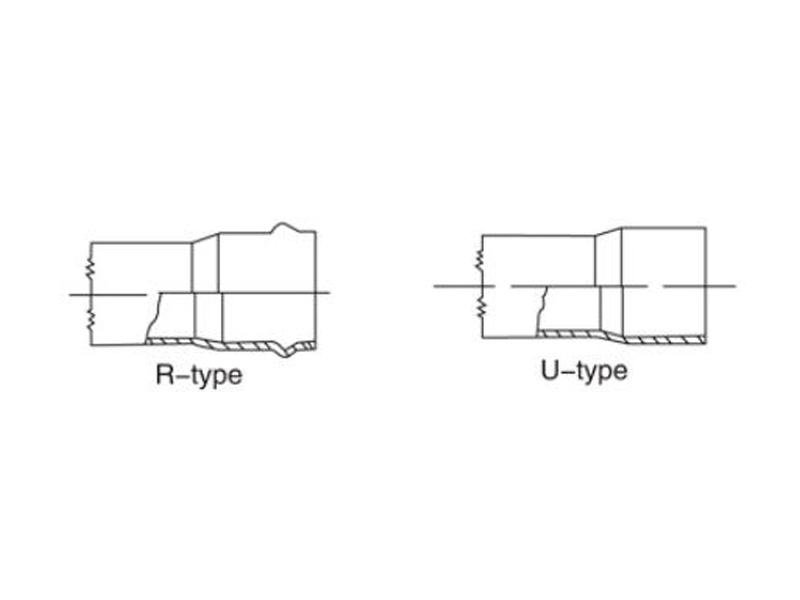

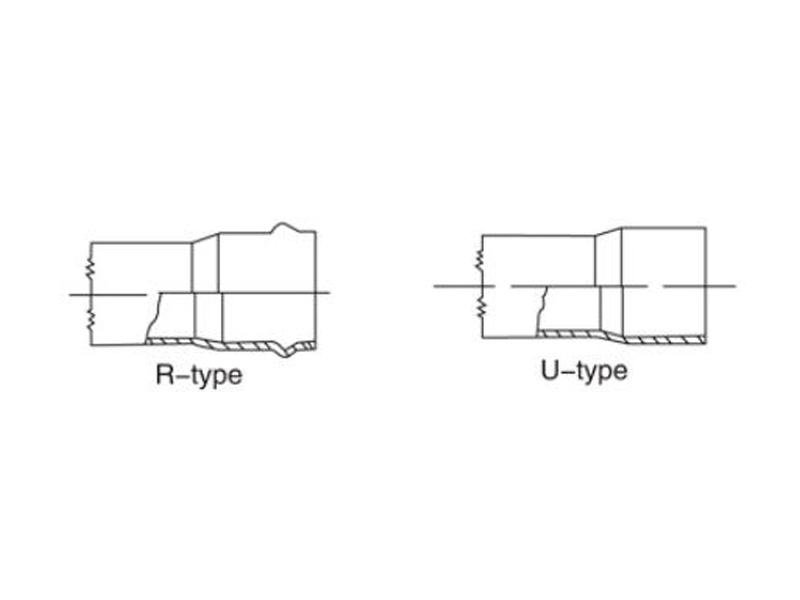

U-type | Pushing the mould into pipe directly |

| R-type | With ext - pressure and collapsible mandrel | |

| Cooling type | Water – cooling | |

| Machine speed | Max. 120S/pipe |

| No. | Items | YUYU* Desheng |

| 1. | Company scale | Covers an area of 53,000 sq.m. with more than 20 years’ experience for machinery. With over 100 staff group. |

| 2. | Certification | CE; ISO; high-tech enterprise; with patents |

| 3. | Electrical components | Siemens, Mitsubishi, Schneider, Omron, Autonics, etc Taiwan Ashun, Yinchuan Changcheng, Or Taiwan Ashun |

| 4. | R-type working way | 2 ways: suitable for thin and thick wall thickness pipes.No.1 segment in first, after heating, pipe insert on the moulds, segment out, increase ext- pressure to take sharp.No.2 segment out first, after heating, pipe insert on the moulds, increase ext-pressure to take sharp. |

Product detail pictures:

Related Product Guide:

We pursue the administration tenet of "Quality is remarkable, Services is supreme, Status is first", and will sincerely create and share success with all customers for OEM Manufacturer Automatic Pipe Belling Machine - DS500 Belling machine – Yuyu, The product will supply to all over the world, such as: Milan , Hanover , Birmingham , With well educated, innovative and energetic staff, we are responsible for all elements of research, design, manufacture, sale and distribution. By studying and developing new techniques, we are not only following but also leading fashion industry. We listen attentively to the feedback from our customers and provide instant replies. You will instantly feel our professional and attentive service.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.

-

Big Discount Tube Chamfering Machine - DS110S-...

-

OEM Customized Electric Pipe Threader Machine -...

-

Reliable Supplier Single Head Chamfering Machin...

-

China wholesale Chamfering Machine - DS630 Bel...

-

Chinese Professional Making Forming Bending Mac...

-

Chinese wholesale Cnc Bending Machine Price - ...