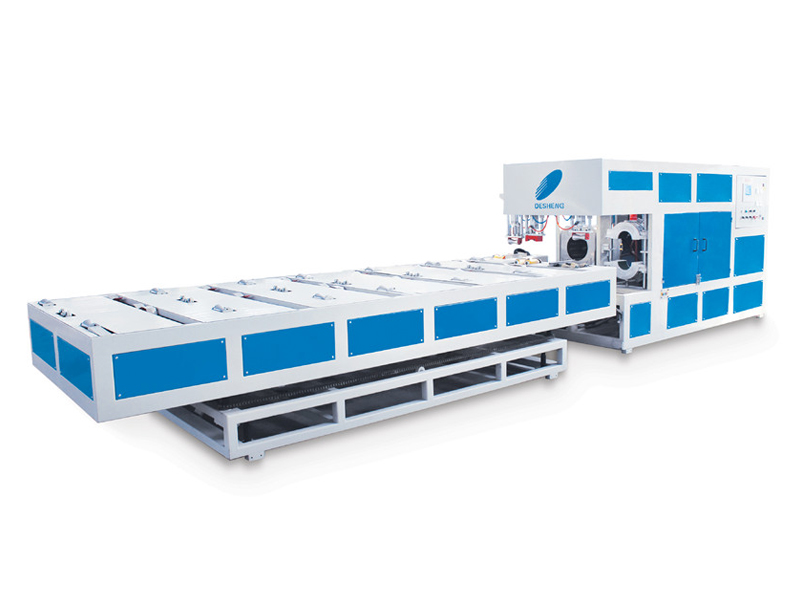

OEM manufacturer Tube Belling Machine - DS160 Belling machine – Yuyu Detail:

| Pipe

standards

|

Model | DS160 |

| standard | U-PVC pipes | |

| Diameter | 40mm – 160mm | |

| Pipe Length | 6m | |

| Heating

|

Heating way | 1 oven (Option: 2 ovens)

Stainless steel body, long service life |

| Pipe Rotary | Clockwise and anti-clockwise | |

| Electrical

|

PLC and Screen | Siemens |

| low-voltage apparatus | Schneider, Omron | |

| Total Power | 12KW | |

| Pneumatic | Compressed air pressure | 0.6Mpa |

| Water | Water pressure | 0.4Mpa |

| Hydraulic | Hydraulic pressure | 5.0Mpa |

| Equipment

appearance

|

Machine type | Automatic, single line, one pipes per cycle |

| Machine dimension | 7350mm(L)×1450mm(W)×1850mm(H) | |

| Machine weight | 2200kg | |

| Operating principle

|

U-type | Pushing the mould into pipe directly |

| R-type | With ext - pressure and collapsible mandrel | |

| Cooling type | Water – cooling | |

| Machine speed | Max. 50S/pipe |

| No. | Items | YUYU* Desheng |

| 1. | Company scale | Covers an area of 53,000 sq.m. with more than 20 years’ experience for machinery. With over 100 staff group. |

| 2. | Certification | CE; ISO; high-tech enterprise; with patents |

| 3. | Electrical components | Siemens, Mitsubishi, Schneider, Omron, Autonics, etc Taiwan Ashun, Yinchuan Changcheng, Or Taiwan Ashun |

| 4. | R-type working way | 2 ways: suitable for thin and thick wall thickness pipes.No.1 segment in first, after heating, pipe insert on the moulds, segment out, increase ext- pressure to take sharp.No.2 segment out first, after heating, pipe insert on the moulds, increase ext-pressure to take sharp. |

| 5. | options |

|

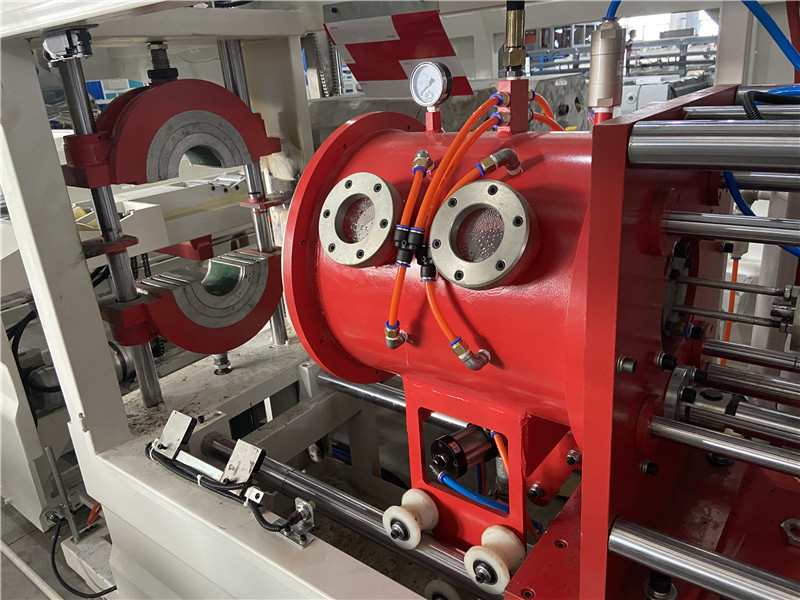

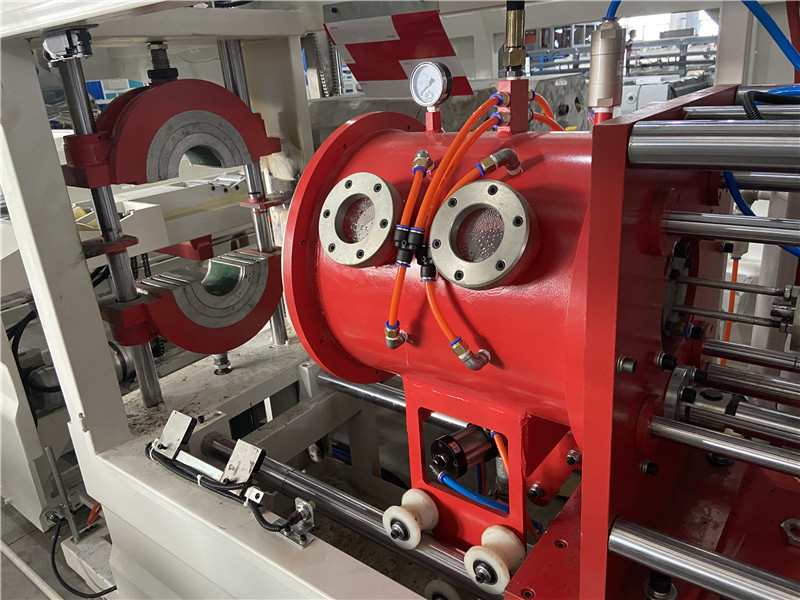

Product detail pictures:

Related Product Guide:

The really abundant projects administration experiences and just one to one particular provider model make the substantial importance of organization communication and our easy understanding of your expectations for OEM manufacturer Tube Belling Machine - DS160 Belling machine – Yuyu, The product will supply to all over the world, such as: UK , Benin , Plymouth , We will do our utmost to cooperate & satisfied with you relying on top-grade quality and competitive price and best after service ,sincerely look forward to cooperating with you and make achievements in the future!

Problems can be quickly and effectively resolved, it is worth to be trust and working together.

-

professional factory for Double Head Tube Chamf...

-

Good Quality Hydro Tester - DS630-HT HYDRO TES...

-

China Cheap price Grooving Machine - DS160-SA ...

-

professional factory for Double Head Tube Chamf...

-

Chinese Professional Automatic Slotting Machine...

-

2019 High quality Hydro Pressure Tester - DS30...