OEM manufacturer Tube Belling Machine - DS160 Belling machine – Yuyu Detail:

| Pipe

standards

|

Model | DS160 |

| standard | U-PVC pipes | |

| Diameter | 40mm – 160mm | |

| Pipe Length | 6m | |

| Heating

|

Heating way | 1 oven (Option: 2 ovens)

Stainless steel body, long service life |

| Pipe Rotary | Clockwise and anti-clockwise | |

| Electrical

|

PLC and Screen | Siemens |

| low-voltage apparatus | Schneider, Omron | |

| Total Power | 12KW | |

| Pneumatic | Compressed air pressure | 0.6Mpa |

| Water | Water pressure | 0.4Mpa |

| Hydraulic | Hydraulic pressure | 5.0Mpa |

| Equipment

appearance

|

Machine type | Automatic, single line, one pipes per cycle |

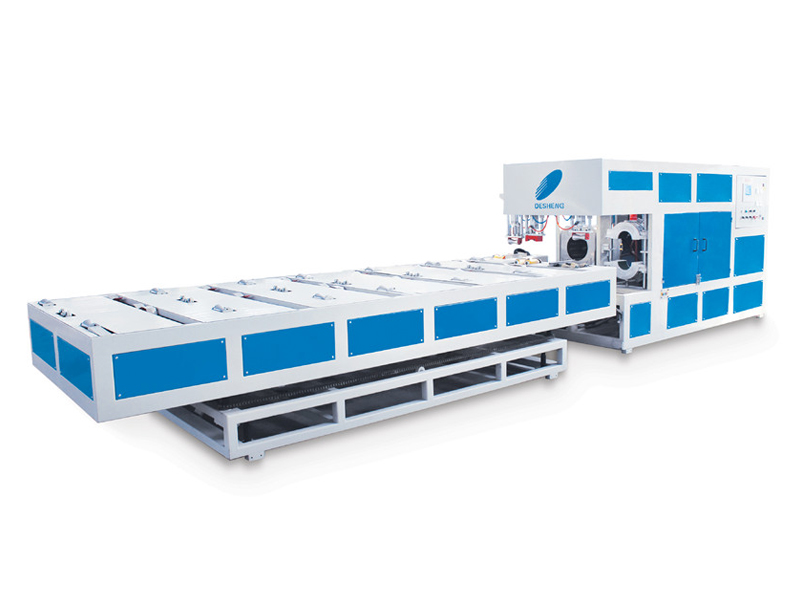

| Machine dimension | 7350mm(L)×1450mm(W)×1850mm(H) | |

| Machine weight | 2200kg | |

| Operating principle

|

U-type | Pushing the mould into pipe directly |

| R-type | With ext - pressure and collapsible mandrel | |

| Cooling type | Water – cooling | |

| Machine speed | Max. 50S/pipe |

| No. | Items | YUYU* Desheng |

| 1. | Company scale | Covers an area of 53,000 sq.m. with more than 20 years’ experience for machinery. With over 100 staff group. |

| 2. | Certification | CE; ISO; high-tech enterprise; with patents |

| 3. | Electrical components | Siemens, Mitsubishi, Schneider, Omron, Autonics, etc Taiwan Ashun, Yinchuan Changcheng, Or Taiwan Ashun |

| 4. | R-type working way | 2 ways: suitable for thin and thick wall thickness pipes.No.1 segment in first, after heating, pipe insert on the moulds, segment out, increase ext- pressure to take sharp.No.2 segment out first, after heating, pipe insert on the moulds, increase ext-pressure to take sharp. |

| 5. | options |

|

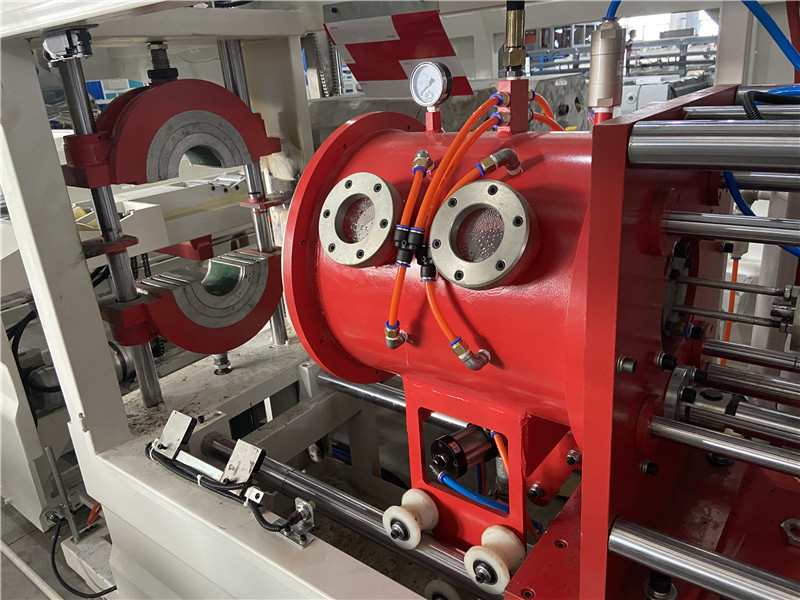

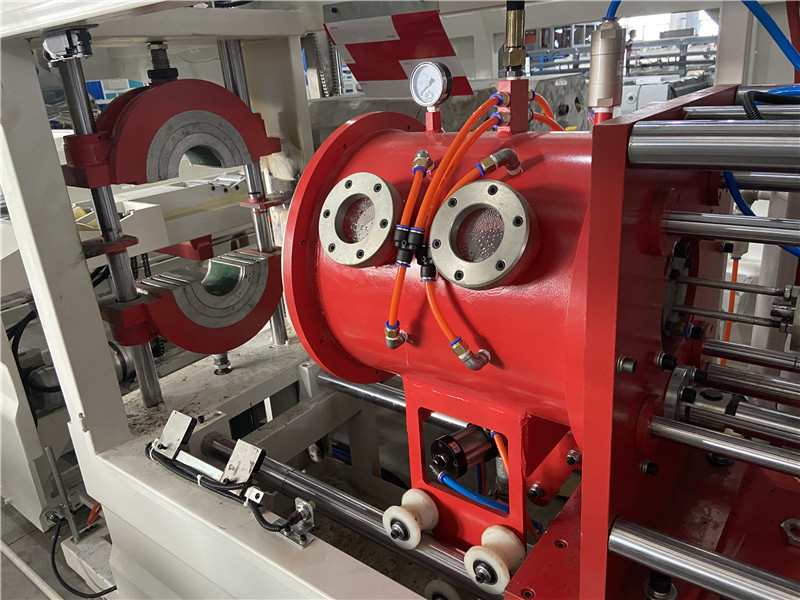

Product detail pictures:

Related Product Guide:

We are going to make every single effort for being excellent and excellent, and accelerate our ways for standing while in the rank of international top-grade and high-tech enterprises for OEM manufacturer Tube Belling Machine - DS160 Belling machine – Yuyu, The product will supply to all over the world, such as: Sweden , Holland , Macedonia , We have sufficient experience in producing products according to samples or drawings. We warmly welcome customers from home and abroad to visit our company, and to cooperate with us for a splendid future together.

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!

-

2019 wholesale price Automatic Thread Cutting M...

-

Excellent quality Automatic Pvc Pipe Belling Ma...

-

Factory wholesale Automatic Rieber Belling Mach...

-

China wholesale Chamfering Machine - DS630 Rie...

-

OEM/ODM Supplier Mechanical Slotting Machine - ...

-

Fixed Competitive Price Rieber Ring Belling/Soc...