Professional Design Rubber Ring Belling Machine - DS630 Belling machine – Yuyu Detail:

| Pipe

standards

|

Model | DS630 |

| standard | U-PVC pipes | |

| Diameter | 315mm – 630mm | |

| Pipe Length | 6m | |

| Heating

|

Heating way | 1 oven (Option: 2 ovens)

Stainless steel body, long service life |

| Pipe Rotary | Clockwise and anti-clockwise | |

| Electrical

|

PLC and Screen | Siemens |

| low-voltage apparatus | Schneider, Omron | |

| Total Power | 40KW | |

| Pneumatic | Compressed air pressure | 0.6Mpa |

| Water | Water pressure | 0.4Mpa |

| Hydraulic | Hydraulic pressure | 8.0Mpa |

| Equipment

appearance

|

Machine type | Automatic, single line, one pipes per cycle |

| Machine dimension | 8600mm(L)×2970mm(W)×2250mm(H) | |

| Machine weight | 8000kg | |

| Operating principle

|

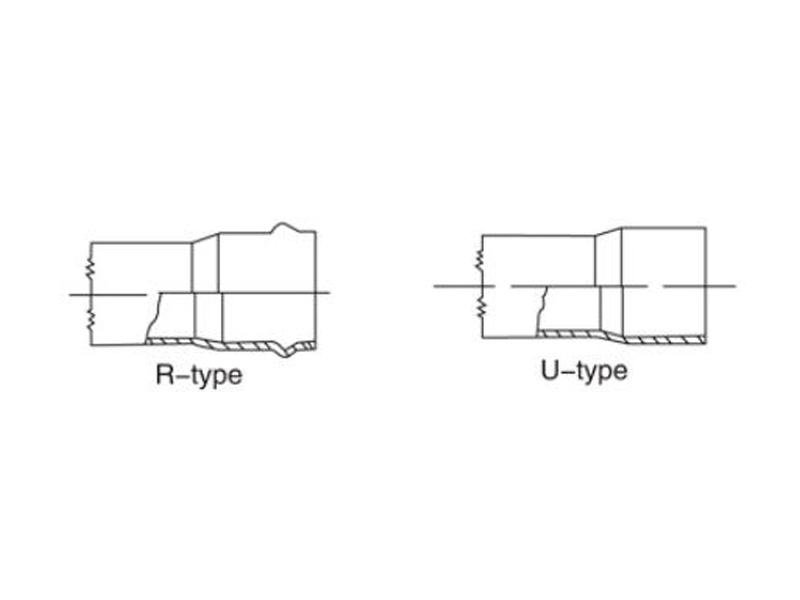

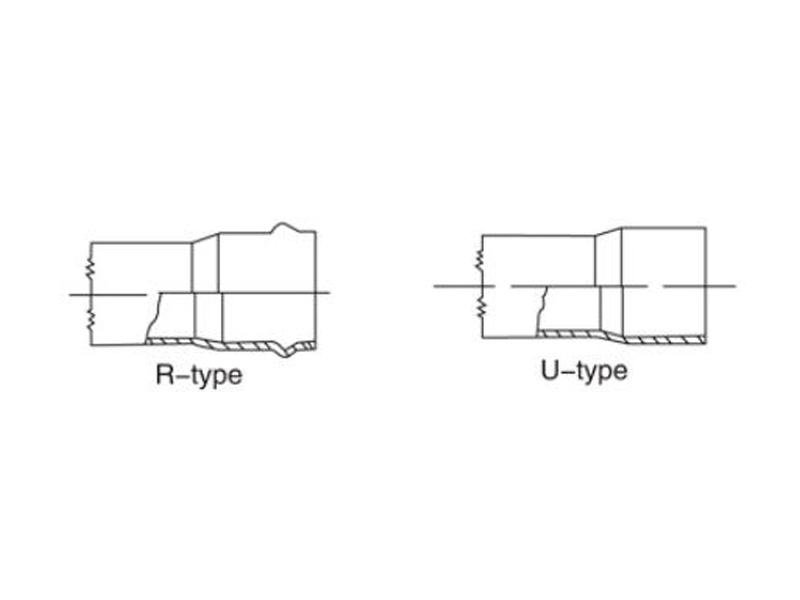

U-type | Pushing the mould into pipe directly |

| R-type | With ext - pressure and collapsible mandrel | |

| Cooling type | Water – cooling | |

| Machine speed | Max. 300S/pipe |

| No. | Items | YUYU* Desheng |

| 1. | Company scale | Covers an area of 53,000 sq.m. with more than 20 years’ experience for machinery. With over 100 staff group. |

| 2. | Certification | CE; ISO; high-tech enterprise; with patents |

| 3. | Electrical components | Siemens, Mitsubishi, Schneider, Omron, Autonics, etc Taiwan Ashun, Yinchuan Changcheng, Or Taiwan Ashun |

| 4. | R-type working way | 2 ways: suitable for thin and thick wall thickness pipes.No.1 segment in first, after heating, pipe insert on the moulds, segment out, increase ext- pressure to take sharp.

No.2 segment out first, after heating, pipe insert on the moulds, increase ext-pressure to take sharp. |

Product detail pictures:

Related Product Guide:

Gaining customer satisfaction is our company's aim forever. We will make great efforts to develop new and top-quality products, meet your special requirements and provide you with pre-sale, on-sale and after-sale services for Professional Design Rubber Ring Belling Machine - DS630 Belling machine – Yuyu, The product will supply to all over the world, such as: Vancouver , Toronto , Casablanca , We'd like to invite customers from abroad to discuss business with us. We can provide our clients with high quality products and excellent service. We are sure that we will have good cooperative relationships and make a brilliant future for both parties.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.