professional factory for Double Head Tube Chamfering Machine - DS1000 Belling machine – Yuyu Detail:

| Pipe

standards

|

Model | DS1000 |

| standard | U-PVC pipes | |

| Diameter | 630mm – 1000mm | |

| Pipe Length | 6m | |

| Heating

|

Heating way | 1 oven (Option: 2 ovens)

Stainless steel body, long service life |

| Pipe Rotary | Clockwise and anti-clockwise | |

| Electrical

|

PLC and Screen | Siemens |

| low-voltage apparatus | Schneider, Omron | |

| Total Power | 73KW | |

| Pneumatic | Compressed air pressure | 0.6Mpa |

| Water | Water pressure | 0.4Mpa |

| Hydraulic | Hydraulic pressure | 8.0Mpa |

| Equipment

appearance

|

Machine type | Automatic, single line, one pipes per cycle |

| Machine dimension | 10000mm(L)×4600mm(W)×2570mm(H) | |

| Machine weight | 15000kg | |

| Operating principle

|

U-type | Pushing the mould into pipe directly |

| R-type | With ext - pressure and collapsible mandrel | |

| Cooling type | Water – cooling | |

| Machine speed | Max. 900S/pipe |

| No. | Items | YUYU* Desheng |

| 1. | Company scale | Covers an area of 53,000 sq.m. with more than 20 years’ experience for machinery. With over 100 staff group. |

| 2. | Certification | CE; ISO; high-tech enterprise; with patents |

| 3. | Electrical components | Siemens, Mitsubishi, Schneider, Omron, Autonics, etc Taiwan Ashun, Yinchuan Changcheng, Or Taiwan Ashun |

| 4. | R-type working way | 2 ways: suitable for thin and thick wall thickness pipes.No.1 segment in first, after heating, pipe insert on the moulds, segment out, increase ext- pressure to take sharp.

No.2 segment out first, after heating, pipe insert on the moulds, increase ext-pressure to take sharp. |

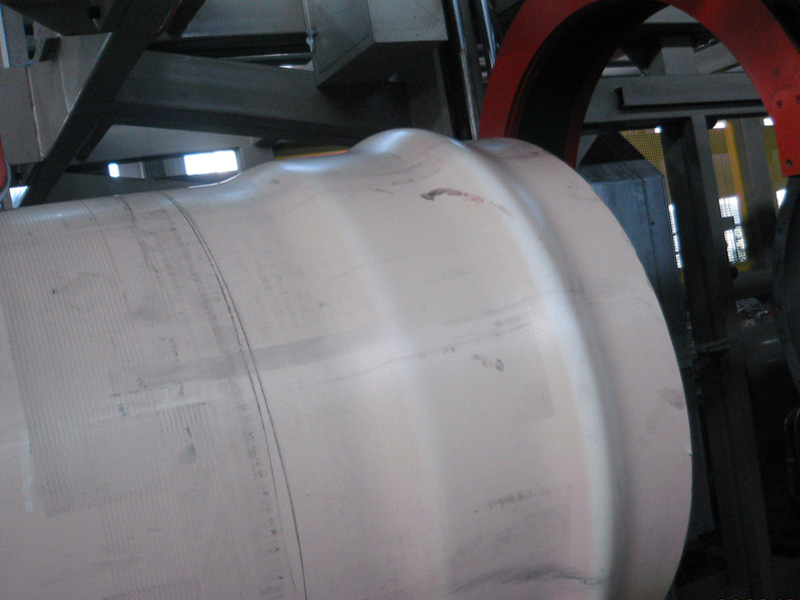

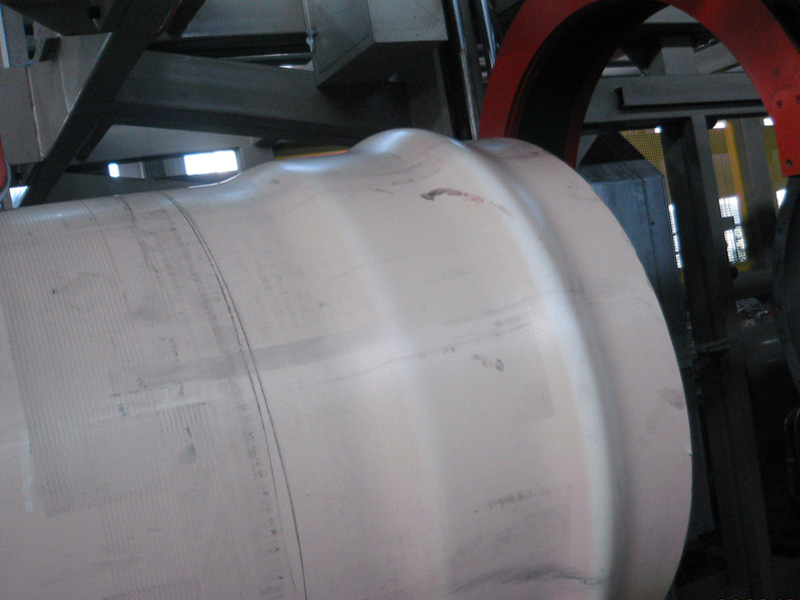

Product detail pictures:

Related Product Guide:

We keep on with the basic principle of "quality to start with, support very first, continuous improvement and innovation to meet the customers" for your management and "zero defect, zero complaints" as the quality objective. To great our service, we offer the items with all the superior top quality at the reasonable selling price for professional factory for Double Head Tube Chamfering Machine - DS1000 Belling machine – Yuyu, The product will supply to all over the world, such as: Georgia , Comoros , Congo , Our tenet is "integrity first, quality best". Now we have confidence in providing you with excellent service and ideal merchandise. We sincerely hope we can establish win-win business cooperation with you in the future!

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.

-

Factory supplied Single Head Chamfering Machine...

-

Quality Inspection for Double Head Chamfering M...

-

OEM China Plastic Expanding Pipe Belling Machin...

-

Good Quality Bending Machine - DS40-bm bending...

-

Professional China Filter Cutting Machine - DS...

-

Cheap PriceList for Water Pipe Belling Machine ...